SUSTAINABLE

Our Products

mycon Products Set an Example for Sustainability

Fossil energy production causes climate changes that are already clearly noticeable today. On the other hand, renewable energies will not be able to satisfy the global hunger for energy for a long time yet. Power generation by waste incineration plants is expected to last for a long time. To bridge the gap, gas-fired power plants will also be needed to generate energy for a longer period of time.

``The way to quickly relieve the environment is to find new technical solutions to reduce energy consumption.``

mycon has been following this path for years and has developed new processes to increase energy efficiency and reduce energy consumption. These processes, most of which are patented, are already being used nationally and internationally.

ControlMaster

The mycon algorithm ControlMaster monitors heat exchangers of all kinds continuously, calculating optimal cleaning intervals. This ensures heat exchangers can always be maintained at the highest level of performance. In addition, the ControlMaster delivers a prompt warning of any partial loss of function by the heat exchanger, preventing possible operating disruptions.

``Using the ControlMaster in conjunction with mycon cleaning technology can lower energy costs by 30 percent or more.``

JetMaster & JetBoy Product Series

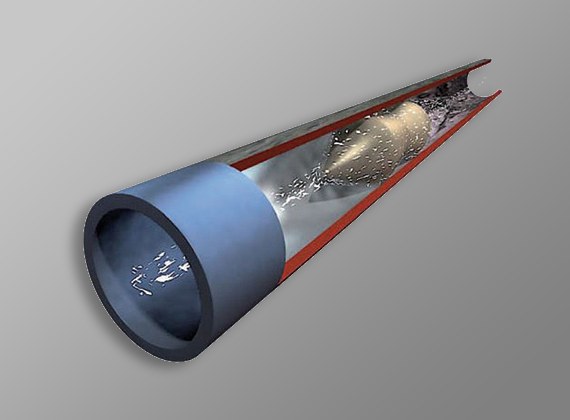

IceMaster

Our IceMaster cleaning devices require 5 to 60 kg of liquid carbon dioxide per hour of use, depending on the device type. Generally, carbon dioxide is recovered from waste gases, for instance, from the chemical industry. Therefore, this represents an environmentally-friendly way to reuse existing carbon dioxide.

Using CO2, which is already available as a blasting agent eliminates the need for solid blasting agents or chemical cleaning agents, which also helps reduce environmental impact.