Waterless blasting system

Specifications

- Cleaning performance: 3-12 m per minute.

- Pipe diameter: DN 4 mm – DN 150 mm.

- Air consumption: 2 m³/min onwards.

- Eco-friendly: As the TubeMaster system operates without water, the costs and environmental impacts associated with water consumption, wastewater disposal, and treatment of cleaning chemicals are eliminated.

- Gentle cleaning: The jetting system utilizes kinetic energy to dislodge deposits and contaminants from the tubes without damaging or scratching the surfaces. This preserves the lifespan of the tube bundle heat exchangers and enhances heat transfer efficiency.

- Efficiency: The TubeMaster system enables quick and efficient cleaning of tube bundle heat exchangers, reducing downtime and increasing productivity.

- Versatility: The jetting system can be used for various types of deposits and contaminants, including stubborn deposits such as scale, rust, or corrosion products.

- Ease handling: The TubeMaster system is easy to operate and does not require complicated installation or preparation. It can be quickly deployed and used to clean tube bundle heat exchangers.

- Cost-effectiveness: By reducing downtime, decreasing the need for cleaning chemicals, and eliminating water consumption costs, the TubeMaster system offers a cost-effective solution for cleaning tube bundle heat exchangers.

The TubeMaster from mycon gently cleans shell-and-tube heat exchangers and individual tubes with compressed air and dry ice or various granulates. Blasting media and residues can be collected cleanly by means of a downstream extraction system with a filter unit and filled for disposal or reuse. TubeMaster is also often used when other cleaning methods have not been successful or when wet cleaning is not desired or not possible.

The abrasive used depends on the type and nature of the residues, the tube routing and the tube material. TubeMaster can also clean curved pipes with dry ice and/or special granulates.

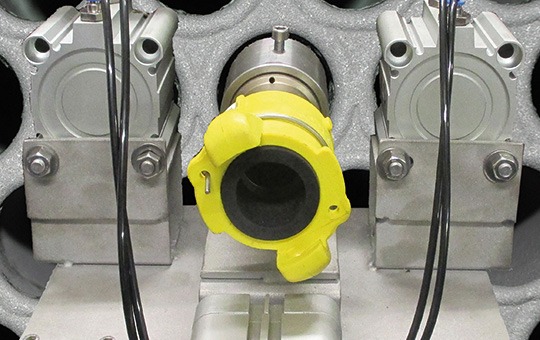

The TubeMaster nozzle is guided through the tube to be cleaned at the speed required to remove the residues by means of a special adapter which is pressed manually or automatically onto the tube mouth. If special granulates are used that are matched to the pipe material, the inner pipe surfaces can be additionally polished.

After Partial Cleaning

After Partial Cleaning Before Cleaning

Before CleaningGraphitpipe before cleaning

Graphitpipe after cleaning

When using the special blasting nozzles specified by mycon, TubeMaster cleans gently. The surface quality of the inner tubes can be additionally improved by using special granulates. Different granulates / grain sizes are used for each tube material. The choice of abrasive is based on the many years of experience of Kipp Umwelttechnik. The blasting medium can be completely collected and filtered on the pipe outlet side together with the removed residues by means of an extraction system. Blasting media and residues can be immediately packaged for disposal.

We have experience in cleaning pipes made of various materials:

Steel, stainless steel, alloy, brass, copper, titanium, special alloys, graphite, glass, plastic of any kind.

TubeMaster AS is the almost fully automated version.

TubeMaster cleans almost completely automatically. The cleaning speed can be adjusted continuously. The constant cleaning speed increases the quality of the cleaning and reduces the abrasive consumption. The cleaning speed can be changed at any time – even during blasting operation.

TubeMaster cleans tubes made of almost all materials. For cleaning graphite tubes, a maximum pressure of 10-20 bar is often specified when using water. This pressure is rarely sufficient for thorough cleaning. TubeMaster can also clean glass tubes, plastic tubes and graphite tubes extremely gently with pressures between 3-7 bar and soft abrasives. When solid granulates are used, even the hardest deposits can be removed.

PressMaster

The new semi-automatic deployment system “PressMaster” for the system TubeMaster makes working with TubeMaster easier and faster. Several systems can be used simultaneously at bigger exchangers.