Digital. Automatic. Energy saving.

On the basis of tens of thousands of data sets sent to us by customers or measured by ourselves, it was possible to develop calculation models for heat transfer apparatus of every design and for every purpose. In the field of energy production (waste incineration plants, power stations) ControlMaster is used to monitor air condensers (Luko). These computational models revealed surprising findings about the effects of even relatively light fouling on the effectiveness of heat exchangers. Together with the Hamburg University of Applied Sciences, mycon is working on converting the existing data into an algorithm. This algorithm then indicates the optimum cleaning time for cleaning with JetMaster or the automated cleaning system JetMaster AS, taking into account the costs for the required cleaning.

- Energy Efficiency: By optimizing cleaning cycles for air conditioning units, it achieves up to 30% energy savings, leading to substantial cost reductions.

- Extended Lifespan: Precise maintenance minimizes corrosion and deposits, prolonging equipment life and reducing the need for costly repairs.

- Environmental Protection: Reduced use of water and chemicals supports sustainable operational practices.

- Safety: Automation minimizes risk to maintenance personnel, promoting a safer workplace.

The ControlMaster is your solution for cost-effective, environmentally friendly, and safe air conditioning maintenance. Experience the future of air conditioning maintenance – efficient, reliable, and sustainable.

Significant energy savings possible with the ControlMaster

Heat exchangers for cooling and air conditioning consume about 24% of the world’s energy. All in all, there is considerable potential for savings here by precisely determining the optimum time for cleaning and immediately following up with effective cleaning.

However, ControlMaster can then also independently start automated cleaning processes, e.g. for hatch cleaning, including all additional measures required for this. This enables considerable energy savings.

Heat exchangers for cooling and air conditioning consume about 24% of the world’s energy. There is a considerable savings potential here by precisely determining the optimal time for cleaning the heat exchangers and immediately cleaning them effectively with JetMaster or JetMaster AS.

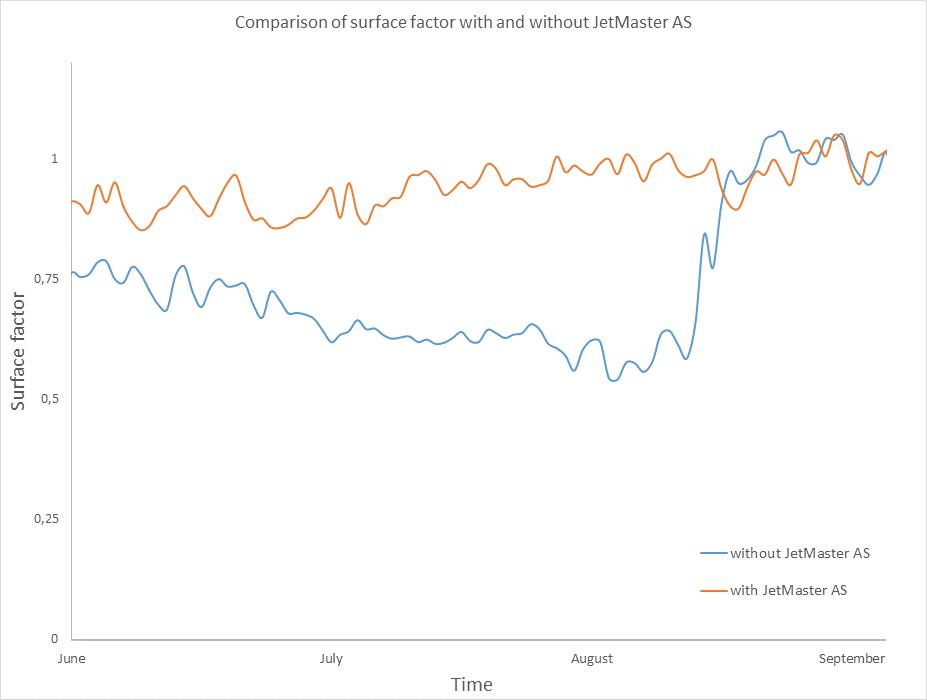

The diagram from 2018 shows the development of the functionality of an air condenser (Luko) with continuous soiling due to environmental influences. The blue line shows the surface factor with twice-yearly cleaning. The orange line shows the surface factor when the cleaning dates set by the ControlMaster monitoring system are adhered to. The cleaning was automated by the mycon JetMaster AS cleaning system. The diagram shows a significant improvement in the function of the heat transfer system due to the cleaning. The ControlMaster monitoring algorithm, together with the mycon JetMaster or JetMaster AS cleaning system, enables a significant increase in energy efficiency and thus considerable energy savings.

Digital monitoring of heat exchanger systems

Revolutionizing Industrial Solutions: Innovative Developments in Monitoring, Cleaning, and Automation by mycon GmbH

We specialize in pioneering advancements for monitoring, cleaning, cooling, coating, and decoating industrial plants. Our solutions are targeted and highly efficient. Operating as a sister company to Kipp Umwelttechnik GmbH, mycon GmbH is actively involved in the development, production, and sale of innovative products and automation techniques within the industrial sector. Drawing on extensive experience in industrial cleaning and services, we have successfully developed multiple systems and secured patents with international recognition. As part of the collaboration with FilterMaster DPF, a division of Kipp Umwelttechnik GmbH, mycon GmbH utilizes its devices to clean particulate filters and industrial filters.