JetMaster cleans air conditioning systems for the French national railway company SNCF

mycon GmbH employs the JetMaster method and successfully cleans air conditioning systems in the trains run by Société nationale des chemins de fer français (SNCF).

Bielefeld 03.02.2016. The French national railway company SNCF attaches great importance to the subject of sustainable environmental management. The company shows high levels of interest in environmental protection and measures to save energy; amongst other aspects, it works intensively on delivering effective measures for the management of water and responsible handling of resources. The company mycon, therefore, was able to impress SNCF with its cleaning method JetMaster, which spares resources and protects the environment when cleaning fin heat exchangers in air conditioning systems. JetMaster fulfilled these fundamental requirements right from the beginning with a cleaning process without chemicals by using only compressed air and the minimum addition of clear water.

Project planning is preceded by intensive tests

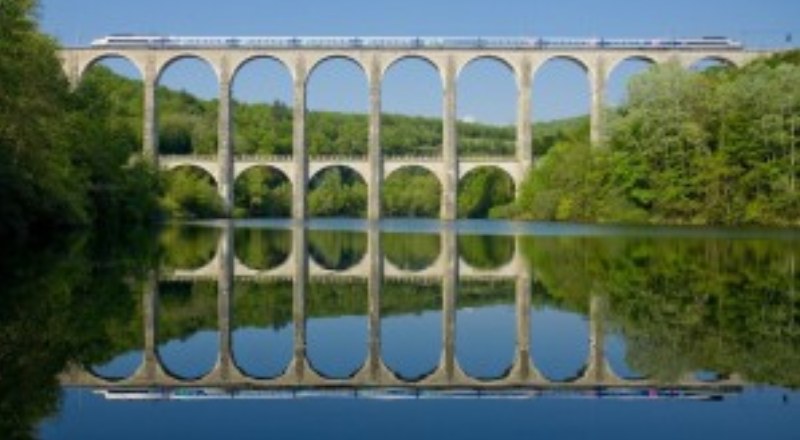

SNCF is a world leader amongst train companies with approx. 249,000 employees. It covers almost all of the rail traffic in France and Monaco and, amongst others, operates the renowned high-speed train, the TGV. The company is also active internationally. mycon and its cleaning method JetMaster first made contact with SNCF at a trade fair for the railway sector in 2012.

SNCF received the first JetMaster appliance for inspection and a test phase mid-2014. SNCF engineers then worked out specific certification processes for JetMaster for the railway sector. mycon then equipped the process especially to SNCF’s requirements. Following a year trial period – first in Paris and then also in Rennes and Villeneuve St. Georges- SNCF became convinced of the benefits and operational capability of the JetMaster method in the railway sector. In the railway sector, JetMaster also cleans effectively, cleanly and quickly. JetMaster helps to avoid reduction in performance or air conditioning system breakdowns. Its mode of action is superior to that of high-pressure cleaners, which use compressed air or water. The low use of water from 0.20 l per minute is particularly efficient when used inside train carriages.

Soft pressure results in high levels of cleaning power

JetMaster, the cleaning method developed for fin heat exchangers, works with compressed air and the smallest amounts of water between 0.2 – 0.75 litres per minute. This cleaning method is suitable for sensitive areas because of the minimal amounts of water used. As water appears in vaporised form, cleaning is also possible in areas where water is normally a disruptive factor.

The cleaning process does not damage the sensitive fins. Not only are surfaces cleaned but also the whole depth of the installation. JetMaster can even clean fin heat exchangers with significant construction depth of up to 840 mm. Oily contamination or extreme deposits of calcium do not present any problems either and can be removed fully and without damage.

Oliver Kipp, mycon GmbH’s managing director, adds: “When cleaning fin heat exchangers, which are on top or under the train, the binding of dust achieved by the JetMaster’s nozzle jet is an important factor for health and safety at work as well as for its high levels of cleaning efficiency.“

Regular cleaning as a maintenance measure

Contaminations of fin heat exchangers form a layer, which significantly reduces energy efficiency and therefore raises energy costs quickly by more than 20%. Furthermore, contaminants cause corrosion, which results in a shorter unit service life. Regular cleaning represents saving energy as well as preventative maintenance.

The JetMaster method assists SNCF with immediate effect in its endeavour to realise the targets of the 10-year action plan, determined in the year 2012, which includes amongst others the reduction in energy consumption of greenhouse gas emissions.