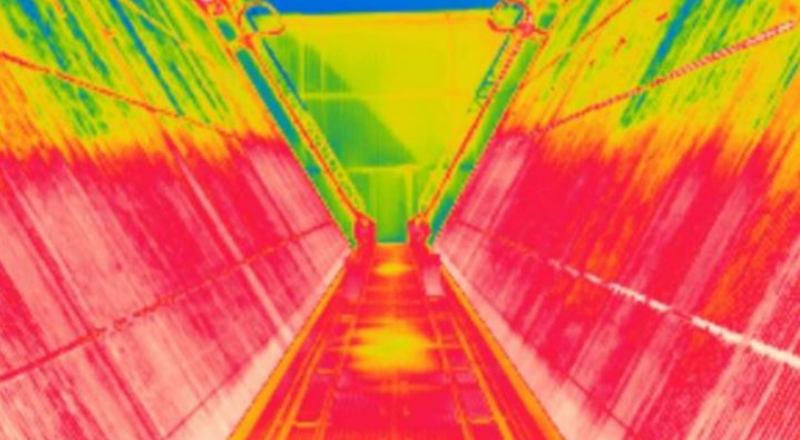

Cleaning a cooler with the JetMaster method

It is no longer possible to stop climate change through technical improvements alone. But even small steps towards increasing efficiency in the generation of energy and towards saving energy can slow down the pace of climate change so that the necessary upheaval with regard to generating and consuming energy will be less painful than it would otherwise be. mycon products contribute to increasing the efficiency of heat transfer devices.

As a consequence of climate change, considerably more energy is required for air conditioning in buildings and cooling in the industrial sector. In countries in the Gulf region and in parts of Asia, air conditioning/ventilation during summer already makes up around 50% of the total consumption of energy; globally, it is responsible for around 22%. Many air conditioning and cooling systems are air-cooled using ventilation. As a result, more energy is required for air conditioning in the first place. Increasing outdoor temperatures due to climate change also mean that additional energy is required for the ventilation necessary to cool the needed heat transfer devices. This dual effect increases the total amount of energy needed to operate systems of this kind significantly, and the energy requirement will continue to rise due to climate change.

Clean heat transfer devices save on energy

This means that the cleanliness of heat transfer devices is all the more important. Soiling on the blades forms an insulating layer that impairs the dissipation of heat into the ambient air by up to 30% or even more.

High-pressure water cleaners with a water consumption of between 10 and 40 litres per minute and per jet nozzle are often used for cleaning. In some cases, chemicals are used, too (lathering). This places a burden upon water resources and the environment. Moreover, high-pressure cleaning with water can damage the delicate blades.

Typical damage due to excessive mechanical stress, e.g. due to high-pressure water cleaning

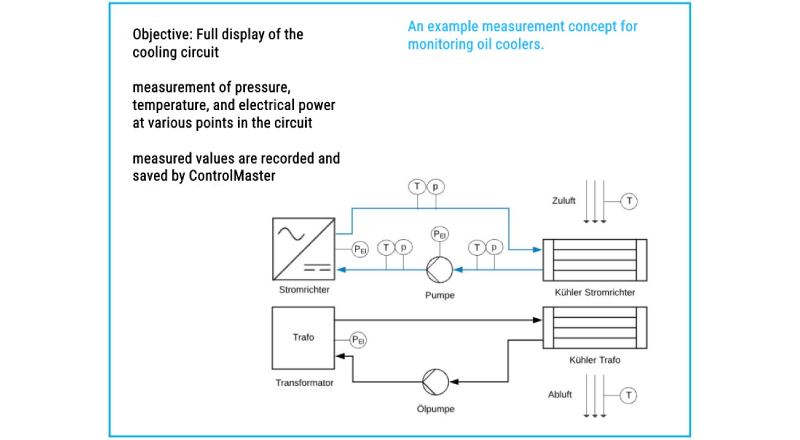

Monitoring with ControlMaster

Monitoring heat transfer devices with ControlMaster allows you to determine the best possible cleaning times. This saves on energy and increases production volumes in the field of energy generation.

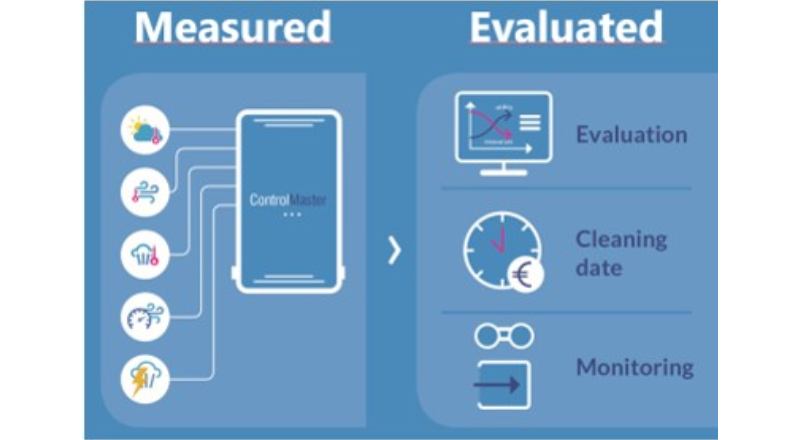

Functional principle of ControlMaster

The cleaning time for the heat transfer devices is determined by means of a visual inspection to a greater or lesser extent. This is supported in part by the evaluation of certain recorded system data. Cleaning always incurs costs. ControlMaster helps you to clean your equipment at the best possible time.

mycon has developed the ControlMaster algorithm for the exact determination of the best possible cleaning dates. ControlMaster can be installed as an automated monitoring unit. This allows heat transfer devices to work as well as they possibly can all year round.

The intensive yet gentle cleaning using mycon’s patented procedure protects the environment and lengthens the service life of heat transfer devices.

mycon has developed JetMaster (for the cleaning of large areas) and JetBoy SP (up to approx. 20 m2 per single area), and JetBoy (evaporators and small registers) for the manual cleaning of heat transfer devices. There is also the JetMaster AS system for fully automated cleaning.

The devices work with the nationally and internationally patented mycon method, using only compressed air (4 to 7 bar) and low quantities of water (around 0.2 to 1 litre per minute) with no chemical additives. This type of cleaning saves on considerable effort for the disposal of wastewater. The low jet pressure and chemical-free cleaning increase the lifetime of the heat transfer devices.

Special combi-devices can even remove hard deposits of limescale from heat transfer devices.

Video – JetMaster cleaning of limescale deposits from a hybrid cooler

Video – removal of heavy oil soiling from a bus intercooler

Video – cleaning of a ventilation and air conditioning heating register with normal soiling

JetMaster AS – intensive but gentle cleaning of heat transfer surfaces with a surface performance of up to 100 m2 per hour to ensure constant high performance and a long lifetime for your systems.

The fully automated JetMaster AS cleaning system is used by customers with large heat transfer devices for between 10 and 25 cleaning cycles per year.

Cleaning time for 100 m2 with normal soiling is around an hour.JetMaster AS arbeitet voll automatisiert im Bereich Energieerzeugung

JetMaster AS provides fully automated cleaning. It is controlled using a PLC. The desired cleaning programme can be selected at the press of a button and the cleaning area can also be entered (if multiple areas exist). The rotors can be automatically placed out of operation to clean the surfaces in the area in question and can then be placed back into operation automatically, too.

The ControlMaster algorithm can be used to directly operate the entire cleaning system along with all required ancillary services.

ControlMaster can perform an advance calculation of the return on investment for an automated cleaning system on the basis of historical data held by the customer as long as the heat transfer device in question has been used for an operating period of at least one year. This makes the purchase/long-term leasing of the equipment free from any risk.

JetMaster AS is a fully automated system in the energy generation area

mycon can provide all devices as follows:

- For purchase

- For a test lease (1 month, cost offset from subsequent purchase)

- For long-term leasing

We’re also happy to advise potential customers. Quotations with performance examples are available on request – fast, detailed, and meaningful.

Images/Video: Kipp Umwelttechnik GmbH/mycon GmbH