Cleaning of a blocked HVAC coil with JetBoy

Cleaning of a normally soiled HVAC heating coil

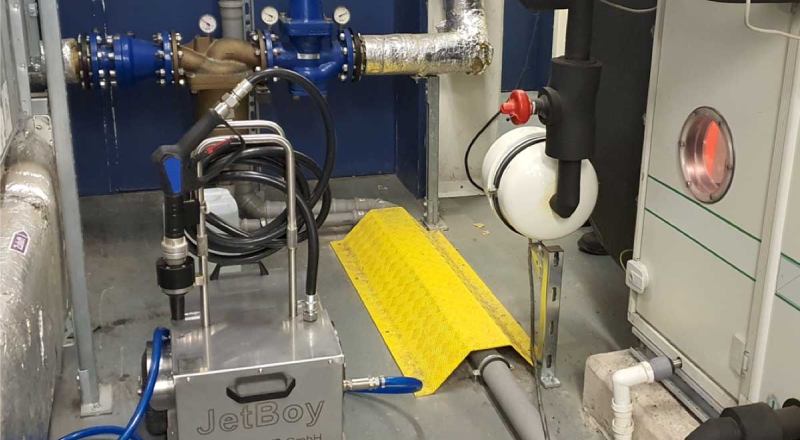

Cleaning in a difficult to access area without compressed air and water supply

The compressors (230 V) are coupled to supply compressed air to the JetBoy when required

The use at plants with difficult access sometimes makes a sufficient compressed air supply difficult. For this requirement, mycon has developed the JetBoy, which can already cope with air volumes from small compressors. These can also be operated on the 230V mains supply.

This means that the cleanliness of heat transfer devices is all the more important. Soiling on the blades forms an insulating layer that impairs the dissipation of heat into the ambient air by up to 30% or even more.

High-pressure water cleaners with a water consumption of between 10 and 40 litres per minute and per jet nozzle are often used for cleaning. In some cases, chemicals are used, too (lathering). This places a burden upon water resources and the environment. Moreover, high-pressure cleaning with water can damage the delicate blades.

Intensive cleaning without large quantities of dirty water

Practical solution example for operating problems due to very heavy loading of a heat recovery coil

HVAC in pharmaceutical logistics

In this case, cleaning with compressed air was not sufficient to remove the clogged dirt from the register. The use of a high-pressure water process was also not possible due to the sensitive lamellas and the quantities of dirty water produced. This is where the JetBoy can show its strength of low water consumption to the fullest. JetBoy requires 0.4 m3 of compressed air at 6 bar and 0.1 l of water per minute.

The cleaning in detail

Backside of the register with radiated soiling

Backside of the register with outgoing cleaning jet

The heavy loading was only evident from the impermissibly high differential pressure. The surfaces looked relatively clean. During the first cleaning pass, fibers and dust were already thrown out of the register. At the end of the cleaning, the discharged contaminants could be seen on the floor behind the exchanger. Lances are available to extend the reach for hard-to-reach areas in HVAC.

The remaining registers are protected by an F7 filter and showed only a normal degree of contamination. Here, the coil surface was cleaned with only one pass. By cleaning the registers, a normal differential pressure of the HVAC could be achieved again.