Suitable Products

IceMaster

PowerMaster

SpeedMaster TC

JetBoy/JetBoy SP

Mini-PowerMaster

DPF Cleaning System

The quality and efficiency of the DPF cleaning system

DPF Cleaning System

Vehicle Cleaning

Paint removal and decoating

Application in the field of vehicle cleaning using PowerMaster and SpeedMaster SR of mycon GmbH.

Forklift truck cleaning and surface preparation (stripping) for repainting purposes.

Application Examples

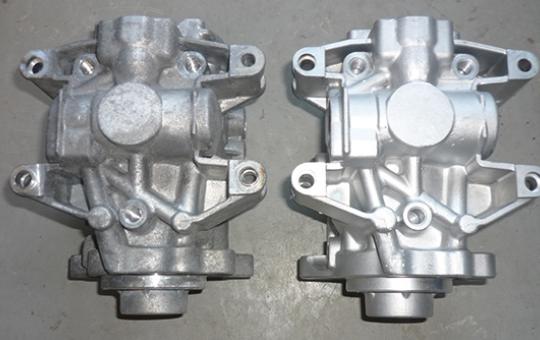

Engine parts after cleaning using PowerMaster

Engine parts after cleaning using PowerMaster Cleaning of engine parts before and after cleaning using PowerMaster

Cleaning of engine parts before and after cleaning using PowerMaster Engine block after cleaning using IceMaster

Engine block after cleaning using IceMaster Engine block before cleaning using IceMaster

Engine block before cleaning using IceMaster After paint removal

After paint removal Before paint removal of a Porsche vintage car

Before paint removal of a Porsche vintage car

Paint removal of an aluminum rim

Cleaning rims using SpeedMaster SR

Paint removal of a Porsche vintage car

Engine block: After cleaning on the left side, before cleaning on the right side

FilterMaster for cars and more

For vehicles up to 3,5 tons

The quality and efficiency of the DPF cleaning system “FilterMaster for cars and more” is impressive. Since no cutting or welding is required, the entire housing, including the pipes, remains intact. The DPF cleaning process previously used for car exhaust diesel particulate filters is therefore is no longer contemporary and no longer competitive in terms of preserving the value invested in them. The method also differs significantly from cleaning equipment and washcoat that rinses the filter with water and/or with water-based or other chemicals. Water can penetrate in the porous “washcoat” – which binds the catalytic metal particles. In contrast “FilterMaster for cars and more” operates with purified compressed air to which a microscopic amount of active agent is added as an aerosol for a short time. The active agent is non-toxic and could even be drinkable, except for its unpleasant taste. Research and practical experience have shown that the active agent will not damage the catalytic surfaces. The fact that the process does not damage exhaust particulate filters has been confirmed by several studies, including one at the University of Paderborn. No damage by the entry of “drinkable chemistry” was shown through the procedure test. The project started in 2011 as part of a two-year grant involving Kipp Umwelttechnik GmbH and the University of Paderborn. The aim of the project was to develop a method for purifying exhaust gas particulate filters without having to dismantle or separate the supply and discharge lines of the filter. This project laid the foundation for the subsequent successful joint development “FilterMaster for cars and more”.

The benefits of the system “FilterMaster for cars” extend to several areas:

- Fully automatic cleaning minimizes the source of errors

- Unsoiled and gentle cleaning maintains the catalytic qualities of the filter

- Cleaning without separating and welding work retains the quality of the filter housing

- Risks of damage, such as caused by melting during the burning process at temperatures of 550°and more are avoided, since the filters are only treated with a temperature of 350° after the cleaning process.

- Quick cleaning times reduce vehicle downtime

- The cost for filter cleaning is reduced

Further information about the systems for diesel particulate filter cleaning from mycon GmbH and the cleaning process can be found in the video on the right hand side and in the scrollable catalogue shown below.

Filtermaster DPF

The service life of a diesel particulate filter (DPF) depends to a large extent on the fact, if the vehicle has been used on short or long distances. In short distances in the long run the system does not reach temperatures, which would result in an optimum combustion of the residues. Cleaning will be necessary if the counter pressure in the filter increases. This will be displayed by the system. The motor could lose performance and switch over to the emergency operating function.