Suitable Products

Mini-PowerMaster

JetMaster/JetMaster AS

IceMaster XLM+LM

JetBoy/JetBoy SP

Trains and Transportation

JetMaster is also available as a silenced and almost splash-proof system.

JetMaster from mycon GmbH is also able to find applications in the trains and transportation sector. Finned heat exchangers can be cleaned without any problems. The PowerMaster unit is used for paint stripping and decoating of surfaces (e.g. wheelsets and bogies).

Make Cleaning More Efficient / Reduce Physical Strain on Employees

mycon GmbH presents new cleaning and coating technologies for the railway sector

Cleaning Oil Cooler

Oil coolers are an important part of the locomotive’s hydraulic system. In diesel-driven locomotives, cooling water is also cooled within the unit. The oil cooler is often very dirty, and conventional high-pressure water cleaning in the installed state often has its trouble here. Cleaning is also exhausting and exhausting.

JetMaster has also cleaned oil coolers successfully, quickly and gently in the installed condition. The cleaning time is usually only 10-15 minutes. But this cleaning work has also been exhausting so far.

mycon has now improved these processes. The jet nozzle of the JetMaster is now positively guided and moved over the exchanger’s surface by means of a special lance. The physical load with the cleaning, which is accomplished in addition still in bent attitude, is thereby strongly reduced.

Cleaning Heat Exchanger Air Conditioning Systems / Other Coolers

JetMaster operates at high blasting speed; the abrasive used in the unit is specially pre-treated water (normal drinking water quality). The high speed of the nozzle jet leads to a higher noise level, at least for the operator. Hearing protection is therefore mandatory. However, the noise level is already greatly reduced at a distance of 10m. mycon has now developed nozzle attachments, especially for the railway sector, which reduces the noise level even further. In addition, the amount of spray water is reduced, which is already low in terms of the cleaning principle when using the JetMaster due to the low amount of water used of less than 1 litre per minute.

Cleaning Heat Exchanger Air Conditioning Systems / Other Coolers

JetMaster operates at high blasting speed; the abrasive used in the unit is specially pre-treated water (normal drinking water quality). The high speed of the nozzle jet leads to a higher noise level, at least for the operator. Hearing protection is therefore mandatory. However, the noise level is already greatly reduced at a distance of 10m. mycon has now developed nozzle attachments, especially for the railway sector, which reduces the noise level even further. In addition, the amount of spray water is reduced, which is already low in terms of the cleaning principle when using the JetMaster due to the low amount of water used of less than 1 litre per minute.

Cleaning / Paint Stripping of Bogies, Wheel Sets and Other Surfaces

mycon uses the PowerMaster device with a special blasting nozzle for this area. This blasting nozzle requires only a greatly reduced amount of compressed air and is abrasive. This reduces the development of damp dust, which can be further reduced by an additional nozzle attachment.

Safety / Exposure of Weld Seams for the Purpose of Visual Inspection

With the SpeedMaster device system, mycon offers the option of either cleaning or stripping the paint. The device system can be used both manually and fully automatically.

Safety / Exposure of Weld Seams for the Purpose of Visual Inspection

With the SpeedMaster device system, mycon offers the option of either cleaning or stripping the paint. The device system can be used both manually and fully automatically.

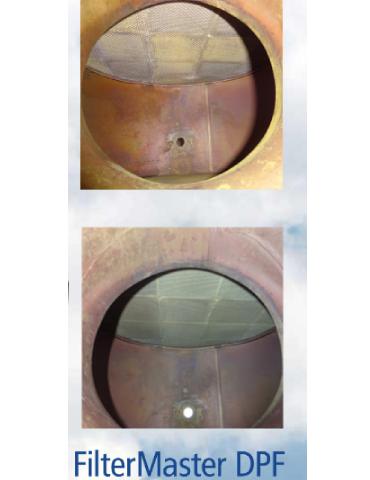

Cleaning of Exhaust Particle Filters / Other Filters

FilterMaster gently, quickly and cost-effectively cleans even dirty exhaust particle filters from locomotives. The cleaning is carried out pressureless with a small amount of non-flammable, non-toxic (even drinkable) liquid. The filter is then dried at a temperature far below that otherwise the required for the filters to burn out. Before and after the cleaning of the exhaust particle filters a complete documentation is made, which is transmitted to the customer.

Decoatings

mycon also offers coatings for the high temperature range. The coatings can also be hydrophobic. Almost all surfaces can be coated.

Decoatings

mycon also offers coatings for the high temperature range. The coatings can also be hydrophobic. Almost all surfaces can be coated.

First Check, Then Rent or Buy For a Longer Period!

mycon offers all devices at a favourable price for a test month at your house. The test rental will be credited in full if the device is subsequently rented/purchased over a long period of time. If required, we will be happy to support you during commissioning.

Cleaning with the SpeedMaster SR.

Cleaning of a finned heat exchanger using the JetMaster from mycon GmbH.

Paint removal of a wheel set using the PowerMaster.

Application Examples

Removal of corrosion protection from bogies for inspection of welding seams

Paint removal of a wheel set

Cleaning of a bogie

Automated cleaning of weld seams of a bogie using IceMaster LM for visual inspection

Cleaning of an oil cooler in disassembled condition

Cleaning of an oil cooler installed in the locomotive

Oil cooler installed in a locomotive before cleaning

The FilterMaster cleaning system from mycon GmbH enables not only the cleaning of various large filters, but also the thorough cleaning of diesel particulate filters from locomotives and railcars.