Suitable Products

JetMaster/JetMaster AS

TubeMaster/ TubeMaster AS

Energy Generation

Issues with the constant functioning of your air-cooled condenser during the warm months? JetMaster AS from mycon GmbH offers the solution. We will be pleased to calculate the possibilities for improving the functionality for you in advance.

JetMaster from mycon GmbH is environmentally friendly and saves resources. The water consumption is extremely low with 0.20 – 1.00l clear water per minute of use. JetMaster works without the addition of chemicals. Thus, the amount of waste water is extremely reduced compared to other aqueous cleaning methods and is only polluted by the mostly harmless soiling of the surfaces in this area. During the examination of the air-cooled condenser in the plant of a customer surprising realizations resulted: The performance of the tested air-cooled condenser dropped between 2 cleanings every 5 months to up to 57% of the rated power due to contamination. This leads to a drop in energy production of up to 25%. If, on the other hand, the air-cooled condenser is cleaned on demand, its output does not fall below 95%, which means that the slumps in production can largely be avoided.

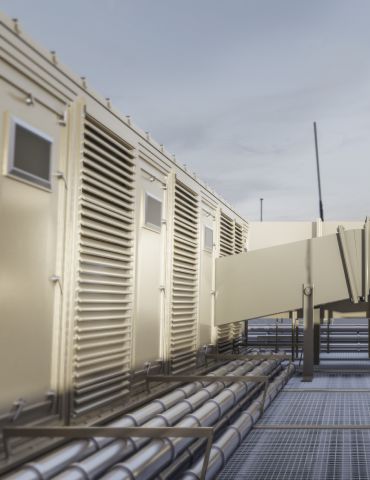

Examples of the automated JetMaster system – cleaning of heat exchangers

Automation examples of the JetMaster

Examples of the automated JetMaster system – cleaning of heavily soiled finned tubes

TubeMaster AS

Application Examples

Cleaning of the membrane wall in a waste incineration plant

Tube bundle heat exchanger made from stainless steel before and after cleaning using TubeMaster

Tube bundle heat exchanger cleaned using TubeMaster by mycon

External view of a polluted steam boiler

Tube bundle heat exchanger for the steam boiler before cleaning

Internal view of the cleaned tube bundle heat exchanger

Air preheater after cleaning with the JetMaster combination system

Air preheater after cleaning with the JetMaster combination system Air preheater before cleaning with the JetMaster combination system

Air preheater before cleaning with the JetMaster combination systemCleaning of cooling towers

The pipes in the cooling tower were temporarily supplied with lime-containing water. As a result, a hard limestone armour had developed around the pipes.

The JetMaster combination system successfully cleaned the outer pipe surfaces.

The zinc coating – which had been destroyed by chemical cleaning – is not attacked by JetMaster.

Exterior view of a cooling tower with removed lime deposits

Removed lime during cooling tower cleaning with the JetMaster combination system

Cooling tower pipes after cleaning